Conectamos

el mundo,

cable a cable

Soluciones de alta tecnología

para el sector del cable

y las comunicaciones

50 años

conectando

contigo

Tu aliado en cableado y comunicaciones

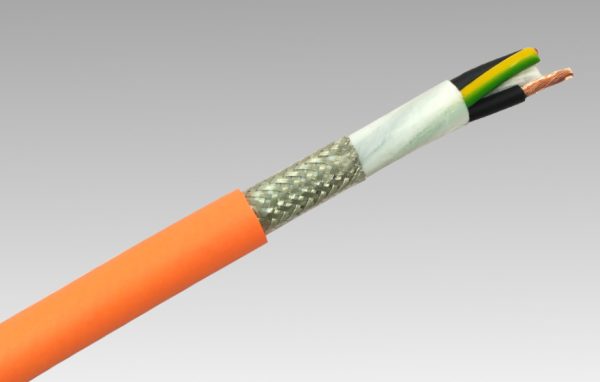

En CERVI, ofrecemos una amplia selección de cables y conductores eléctricos para diversas aplicaciones industriales, desde energía hasta telecomunicaciones, seguridad y más. Como tu proveedor global, disponemos de un amplio inventario de nuestras marcas de confianza, CERVIFLEX y CERVITRONIC.

Nos especializamos en crear soluciones de cableado que superan las normativas internacionales más estrictas como IEC, UL y CSA. Gracias a nuestra experiencia en sectores críticos como aeropuertos, refinerías y energías renovables, somos líderes en ofrecer soporte global y atención personalizada para tus necesidades de cableado.

Llevamos nuestros cables

más allá de las fronteras

Europa, Latinoamérica y Oriente Medio... donde nos necesites

Nos enorgullece ofrecer productos de máxima calidad que cumplen con los más exigentes estándares internacionales. Nuestro enfoque en la innovación y la satisfacción del cliente nos permite adaptarnos a las necesidades específicas de cada región, asegurando que nuestras soluciones lleguen de manera rápida y confiable a cada rincón del planeta.

Calidad y compromiso, sello Cervi

Estamos aquí para brindarte soporte y toda la documentación técnica que necesites.

Tu tranquilidad, nuestra prioridad

En Cervi, encuentra materiales de alta tecnología para cableado y comunicaciones

con certificación CPR.

Manuales

de productos

Guías detalladas para la correcta instalación y mantenimiento de nuestros productos.

Normativas

y regulaciones

Documentos que describen las características de nuestros cables y sus prestaciones en caso de incendio.

DOP (Declaración

de prestaciones)

Información actualizada sobre las regulaciones que cumplen nuestros cables.

Encuéntranos donde nos necesites

08228 Terrassa (Barcelona)

48480 Arrigorriaga (Vizcaya)

(esquina calles A y D)

Sector Industrial Plà de Manyanes

08650 Sallent (Barcelona)

Polígono Industrial Massanassa

46470 Massanassa (Valencia)

Edificio Porta Sevilla

41020 Sevilla

P.I. San Fernando II

28830 San Fernando de Henares, Madrid